We provide a wide range of compounds that enable our clients to manufacture their components in a more eco-friendly way.

Our sustainability approach is flexible and can be customized to meet the specific needs of individual brands and applications.

Some of the sustainable solutions we offer include:

Materials based on recycled content:

Compounds that can be derived from post-consumer and/or post-industrial streams (polypropylene, polyamide, PET, and more).

These compounds are tailored to customer requirements and specifications.

Recycled compounds generally have a significantly lower carbon footprint compared to their virgin counterparts and can be manufactured using 100% renewable energy at some of our production facilities.

Materials that are bio-based or partially bio-based:

A broad selection of compounds derived from renewable raw materials, such as PA1010, PA610, transparent PA12, and others.

These materials have excellent properties, including low moisture absorption, low density, and good resistance to UV and chemicals.

Carbon-neutral solutions (de-carbonizer):

An innovative solution designed to achieve carbon neutrality or reduce carbon footprint. Available for Polytron Long Glass Fibers and Engineering Plastics.

Sustainable solutions for functional polymers:

Bondyram Compatibilizers

– Facilitating high-quality plastic recycling

– Enhancing wood/resin adhesion, mechanical properties, and reducing water absorption

Bondyram® ECO TL

Improving the compatibility of polar polymers like EVOH or PA with polyolefins in recycled mixtures and multi-layer film structures

High-performance compounds:

Improving mechanical properties, heat resistance, and chemical resistance.

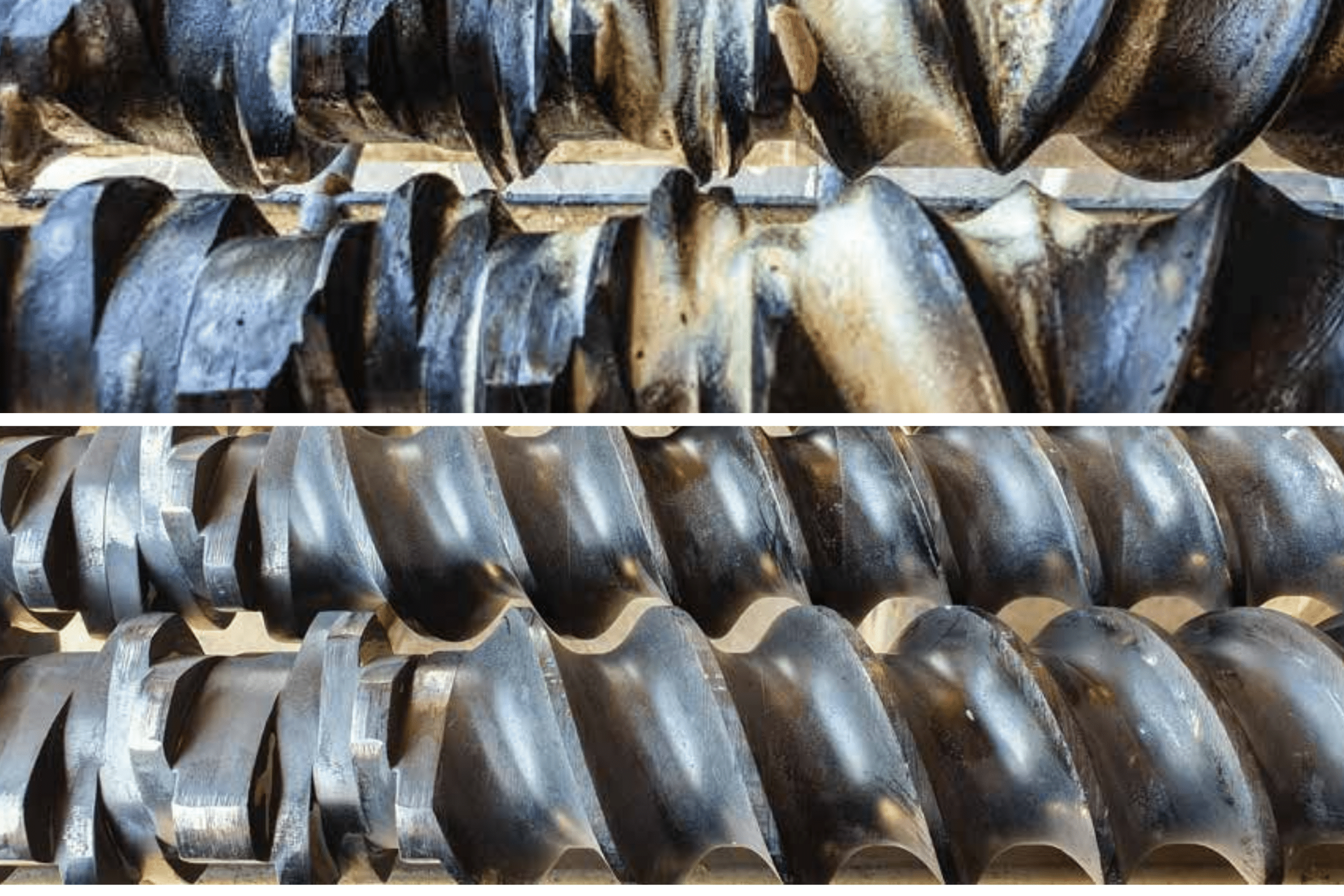

Plustek PAT, PATH, and Polytron materials are intended to replace metal components.