- +420 725 399 533

- info@spzpolymer.cz

- Job Opportunities

- +420 725 399 533

- info@spzpolymer.cz

- Job Opportunities

BONDYRAM® TL - Tie Layer

Adhesive resins enable the combination of dissimilar materials in a multilayer structure.

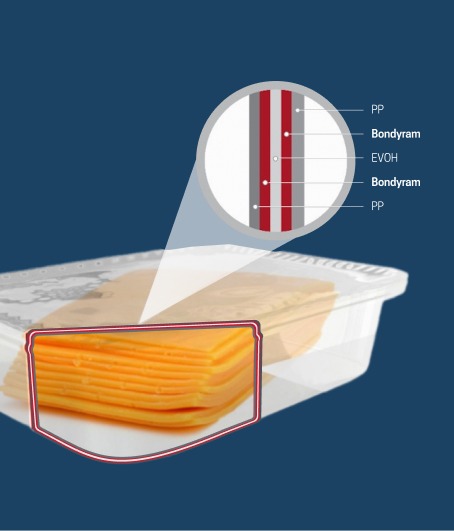

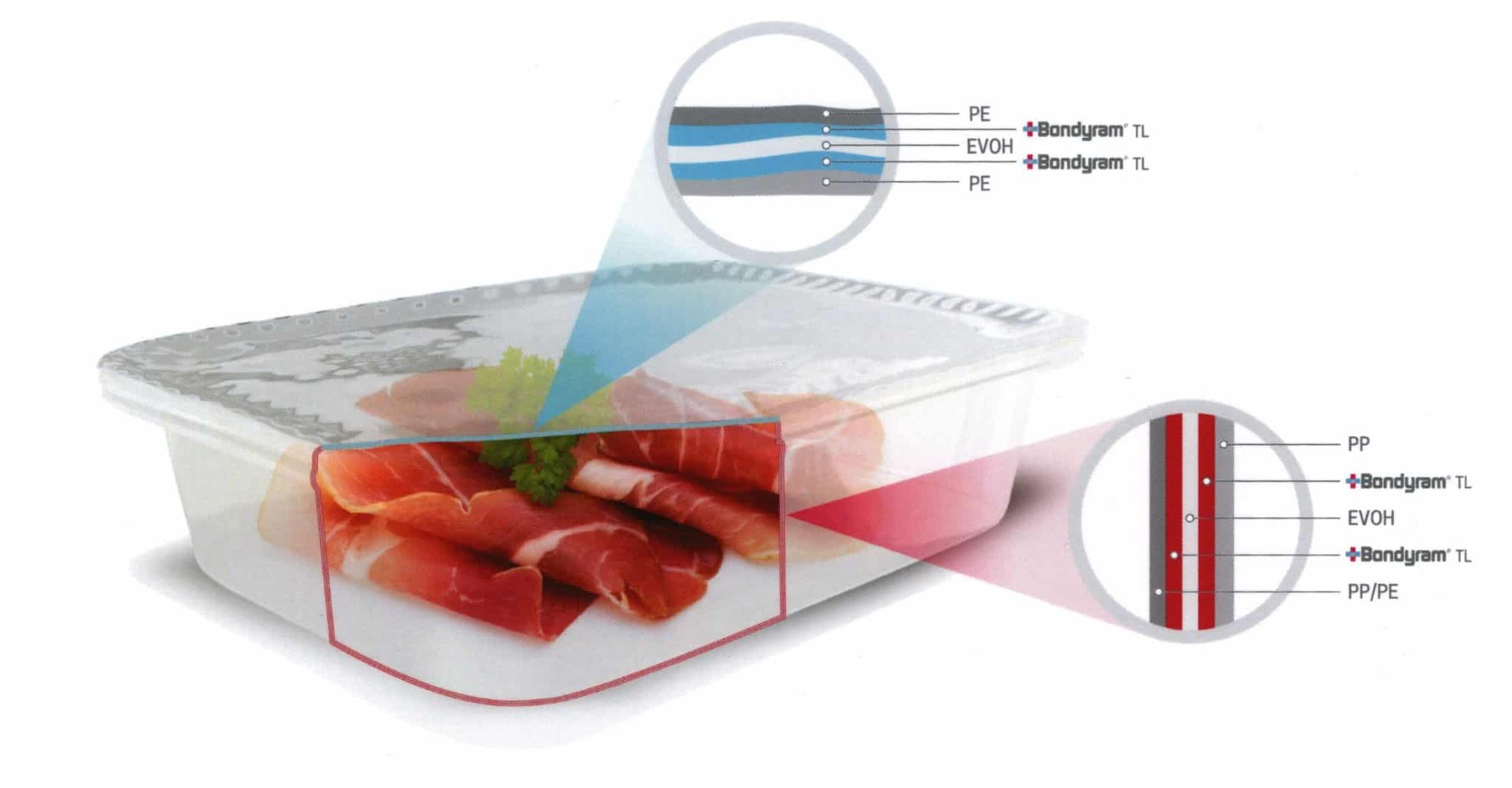

Bondyram® TL is used as a tie layer in coextruded food, cosmetic and pharmaceutical packaging, and also in non-packaging applications such as multilayer pipes and pipe coating, fuel tanks and aluminum composite panels.

Bondyram® TL resins promote bonding between layers in blown and cast films, sheets for thermoforming, blow-molded bottles and tubes, coextruded pipe and pipe coating, as well as in extrusion coating processes.

Typical structures in packaging applications are barrier packages with EVOH or polyamide as the barrier material, tied to polyolefin (PE or PP) layers. Bondyram® TL grades also support bonding of a variety of other materials, including PET, PS and aluminum.

Typical Property Data (Example)

| Property | Unit | ASTM Test method | Bondyram® TL4109E | Bondyram® TL4110 |

|---|---|---|---|---|

|

MFI 190°C / 2.16 Kg

|

gr/10min

|

D1238

|

2

|

1.8

|

|

Density

|

gr/cm3

|

D1505

|

0.905

|

0.905

|

|

Melting Point - DSC

|

ºC

|

DSC

|

117

|

117

|

|

VICAT Softening Point

|

ºC

|

D1525

|

85

|

85

|

|

Shore Hardness D-Scale

|

D2240

|

40

|

40

|

|

|

Maleic Anhydride

|

%

|

FTIR

|

High

|

Very High

|

Processing:

Bondyram® products can

be processed on standard

Polyethylene equipment.

Packaging:

Supplied in pellet from,

20kg, PE bags,

600kg cardboard boxes.

Tie Layers | Ready to use

| Property PE Products | Bondyram® TL4101A | Bondyram® TL4120 | Bondyram® TL3125 | Bondyram® TL3115 |

|---|---|---|---|---|

|

Base Polymer

|

HDPE

|

LLDE

|

MDPE

|

HDPE

|

|

MFI 190°C / 2.16 Kg

|

4.0

|

1.5

|

2.5

|

3.0

|

|

Melting Point °C - DSC

|

127

|

120

|

128

|

130

|

|

Multi Layer Applications

|

Pipes

|

Films&Bottles

|

PEX/Pipes

|

Films/Bottles

|

| Property PE Products | Bondyram® TL1270 | Bondyram® TL1207 | Bondyram® TL1235 |

|---|---|---|---|

|

Base Polymer

|

PP

|

PP

|

PP

|

|

MFI 190°C / 2.16 Kg

|

7

|

4.5

|

4

|

|

Melting Point °C - DSC

|

153

|

167

|

153

|

|

Multi Layer Applications

|

Cast Films

|

Films/Bottles/Sheets

|

Films/Sheets

|

Tie Layers

Bondyram® TL concentrated grades recommended usage (Example)

Concentrate PE Tie Resins (Example)

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F | Shore Hardness D-scale | Maleic Anhydride (%) |

|---|---|---|---|---|---|---|

|

Bondyram® TL4114

|

3.5

|

0.918

|

116/240

|

98/204

|

55

|

High

|

|

Bondyram® TL4108

|

1.5

|

0.918

|

118/244

|

98/210

|

45

|

High

|

|

Bondyram® TL4110

|

1.8

|

0.908

|

117/243

|

85/185

|

40

|

High

|

|

Bondyram® TL4180

|

1.0

|

0.92

|

122/251

|

105/221

|

55

|

High

|

PE | Ready-to-use Tie Resins (Example)

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F | Base Resin |

|---|---|---|---|---|---|

|

Bondyram® TL4808

|

3.0

|

0.917

|

118/244

|

98/210

|

mLLDPE

|

|

Bondyram® TL4122

|

2.2

|

0.92

|

121/251

|

100/212

|

mLLDPE

|

PE | Ready-to-use Tie Resins for Bi-oriented Film (Example)

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F | Shore Hardness D-scale |

|---|---|---|---|---|---|

|

Bondyram® TL4702T

|

3.5

|

0.91

|

114/237

|

86/186

|

38

|

|

Bondyram® TL4706

|

2.2

|

0.89

|

95/203

|

61/141

|

35

|

PP | Polypropylene - BOPP (Example)

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F | Base Resin |

|---|---|---|---|---|---|

|

Bondyram® TL1248

|

4.5

|

0.88

|

145/293

|

108/226

|

rPP

|

PP | Tie Resins (Example)

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F | Base Resin |

|---|---|---|---|---|---|

|

Bondyram® TL1235

|

4.5

|

0.9

|

153/307

|

126/259

|

rPP

|

|

Bondyram® TL1240

|

4.5

|

0.89

|

144/291

|

113/235

|

rPP

|

|

Bondyram® TL1221

|

3.0

|

0.9

|

160/320

|

141/286

|

CoPP/rPP

|

|

Bondyram® TL1350 concentrate

|

18.0

|

0.9

|

149/300

|

85/185

|

CoPP

|

Polystyrene | Ready-to-use Tie Resins (Example)

- These grades are designed as ready-to-use tie layer in co-extrusion

applications, for bonding between EVOH or Polyethylene to

Polystyrene in multilayer structures. - The advantage of these grades is high temperature resistance in hot fill packaging applications as indicated by their high VICAT (>80°C).

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F |

|---|---|---|---|---|

|

Bondyram® TL4401

|

1.5

|

0.95

|

127/261

|

89/192

|

|

Bondyram® TL4402

|

1.4

|

0.94

|

125/257

|

83/181

|

|

Bondyram® TL4403

|

1.6

|

0.92

|

125/257

|

82/180

|

EVA Based Tie Resins (Example)

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F | TL |

|---|---|---|---|---|---|

|

Bondyram® TL9210

|

1.0

|

0.94

|

84/183

|

63/145

|

Concentrate

|

|

Bondyram® TL9203

|

1.5

|

0.94

|

84/183

|

63/145

|

Ready to use

|

Tie Resins for ACP (Aluminium Composite Panels) (Example)

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F | Base Resin |

|---|---|---|---|---|---|

|

Bondyram® TL4313

|

1.0

|

0.944

|

120/248

|

87/189

|

PE

|

|

Bondyram® TL9213

|

1.6

|

0.93

|

92/198

|

61/142

|

EVA

|

PET | Ready-to-use Tie Resins (Example)

Bondyram® EcoTL is especially designed as compatibilized to improve the processability of recycling barrierd

films containing EVOH or polyamide. It can be used in PE or PP films.

| Bondyram TL® Grade | MFI 190°C / 2.16 kg (g/10min) | Density (g/cm3) | Melting Point °C/°F | Vicat Softening Point °C/°F | Tg °C/°F | MAH graft level |

|---|---|---|---|---|---|---|

|

Bondyram® Eco TL100

|

2

|

0.9

|

118/244

|

85/185

|

-

|

High

|

|

Bondyram® Eco TL200

|

1

|

0.86

|

42/108

|

-

|

(-45)-(-65)

|

High

|

Food contact approvals:

Monomers and additives are listed as authorized monomers/additives in Annex I of regulation (EC) No. 10/2011

USA: conform to FDA 21CFR 175.105 (adhesives) for indirect food contact.